官方二維碼

Plastic honeycomb board production line is derivative products by absorbing foreign advanced technology, application development by sheet extrusion production equipment of traditional plastic, innovation and development of Wuhan Lizhi mechanical and electrical equipment company's technical personnel. The product is cater to the low-carbon energy in the new era, because the composite plastic honeycomb plate is rising in developed countries. It saves resources, protects the ecological environment, and is a new type of green decoration materials and packaging materials with low cost. It has big strength to weight ratio, average stress, strong pressure resistance, low thermal conductivity, good shock resistance, light, sound insulation, water absorption and stability over a wide temperature range, so it can be widely used in the current construction, ventilation, sewage treatment, noise, thermal insulation, light bending plate structure, automobile, train light structure. It will have broad prospect of development in our country. The line is to deepen the integration of the plastic sheet coextrusion production technology and vacuum forming technology, and adopts advanced servo control technology. The PLC integrated control and man-machine interface operation. made the operation of the whole production line stable and reliable, with good product quality and high production efficiency.

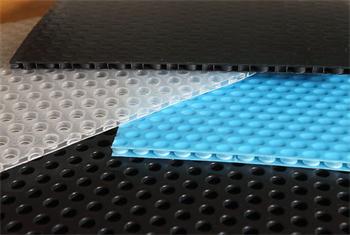

The characteristics of plastic honeycomb plate products:

1, Environmental protection and energy saving: can be applied to sound absorption, noise reduction, heat preservation and other products;

2, Overcome the defects of aluminum honeycomb and paper honeycomb, with reasonable price, good weather resistance, waterproof, blocking the cold bridge etc.;

3, The density is small: because the honeycomb is a porous discontinuous material, and the cross-sectional area of the solid part is very small, so the density of the honeycomb is also very small, so the whole quality is light, and it can meet the lightweight requirements in various fields.

4, Sound insulation, good heat insulation performance in honeycomb sandwich plate used in solid materials, the volume is only 1%--3%. The remaining space is sealed air, because air sound and heat insulation performance is better than any solid material, heat and acoustic propagation have been restricted, so the honeycomb sandwich plate with sound insulation and heat insulation good;

5, Strong damping performance: due to the dense honeycomb board has many competing, like many small beams, each can be dispersed to bear the pressure, and thus play a damping effect.

6, Superior flatness and rigidity: better than the vertical force of the honeycomb core, and each honeycomb plate has numerous fixed honeycombs that do not move. Honeycomb panels contain highly concentrated honeycombs, which can be dispersed to bear all kinds of pressure and make the plate uniformly stressed, which ensures the strength of the pressure and the high flatness when the panel is in a large area.

7, Cool in summer and keep warm in winter: honeycomb panel has much lower thermal conductivity (K value) than other materials, but heat loss is greatly reduced. It is used for building with warm equipment and belongs to environmental protection material.

8, Environmental protection, innocuity and harmlessness: it is made from PP and PC that can be used for making or packing food products. Therefore, it is harmless and harmless, it does not distribute any harmful gases, and it can be recycled and reused.

Plastic extruded honeycomb plate production line configuration list:

1. High speed and high efficiency single screw extruder (multi extrusion)

2. Dry hopper + automatic feeding machine

3, Non stop hydraulic rapid net exchanger

4. Special plate mold

5, Vacuum setting device + mould temperature control device

6, The first traction mechanism

7, Second traction mechanism

8, Third traction mechanism

9. Hot drying setting device

10. Cold wind setting device

11, Fourth traction mechanism

12. The cutting mechanism of sheet material

13. Heap platform

14. Electronic control system

15, Optional: automatic screw feeder + forced feeding hopper, mixing machine, cold water machine + cooling tower, strong crusher and so on.